Products A – Z

Our complete portfolio of products for sports and sport infrastructure.

Solar

TUOsolar solar lighting with a unique design and state-of-the-art technology.

Hydrorock

Hydrorock offers solutions for separating rainwater, water buffering, drainage, infiltration and irrigation by using stone wool as basis material.

Reinforced grass

100%-natural grass cover reinforced with synthetic fibers to increase the hours a play.

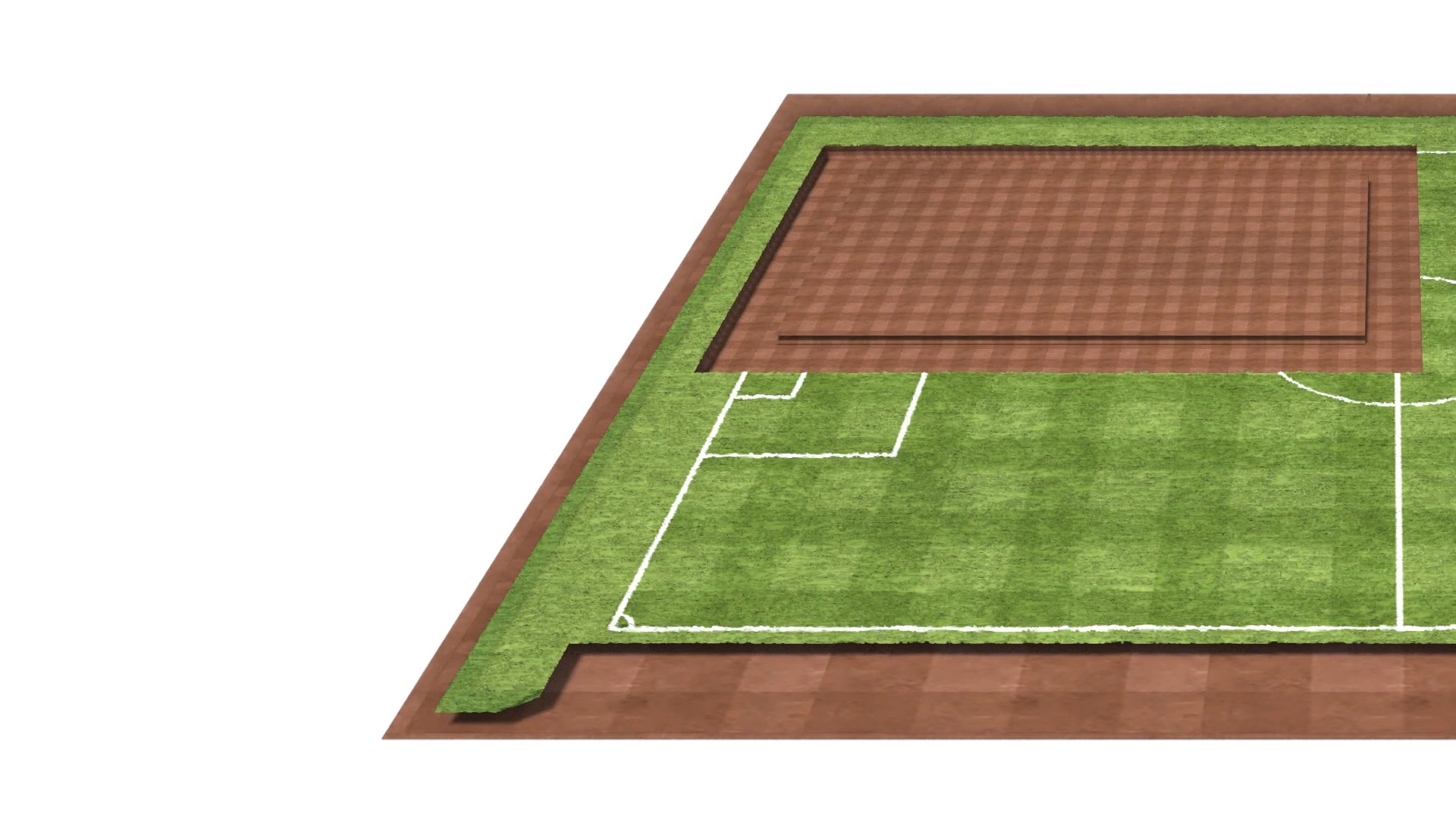

HYDROFIELDS

The 3-in-1 hybrid turf system

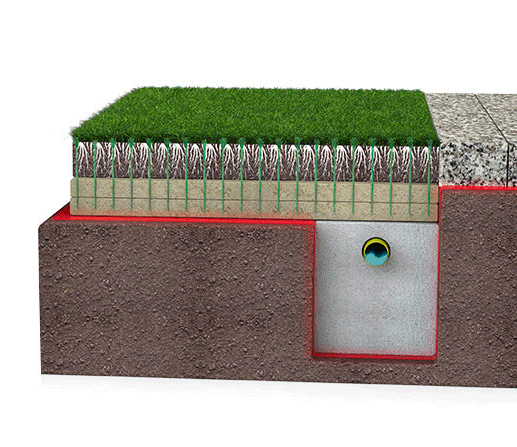

Hydrofields is a patented hybrid system that consists of 3 main elements: a layer of sand/ substrate, reinforcement through artificial grass fibers and a growing layer. The latter makes this system matchless and differentiates Hydrofields from any other hybrid system.

Hydrofields is primarily based on a growing layer of stone wool. Why stone wool? Well, in the first place because it is made of basalt stones and therefore an environmentally friendly and recyclable product. Secondly, because it is stone, it offers a high stability and retains its characteristics over time. But the main reason is its water management capacity: it can buffer 90 liters/m2 of water without any effect on the dimensions and the (product and playing) characteristics.

The Hydrorock panels have a load capacity of up to 8.000 kg/m2 and therefore is a stable layer and a substantial part of the total construction of the natural grass field. Consequently, this leads to costs savings related to the overall construction (simple construction, no drainage system) and lower maintenance costs (such as efficient usage of water).

Hydrorock is a stable supporting layer which functions at the same time as a water management system. Storage of water has no effect on the dimensions, product and playing characteristics. Fibers are cross-linked providing a slope causing the water to run off to the sides of the pitch “automatically”. Stone wool is resistant to humidity and climate impact, keeping its declared properties, shape and volume in the long term.

- Hydrorock stores water and provides oxygen to the root zone which are easy to remove and therefore natural grass is not exposed to water stress

- The availability of water and oxygen encourages roots to grow deep and remain safely below ground, allowing the natural grass to become strong and fully established, whereas the natural grass will grow in the rock wool and thus be even stronger

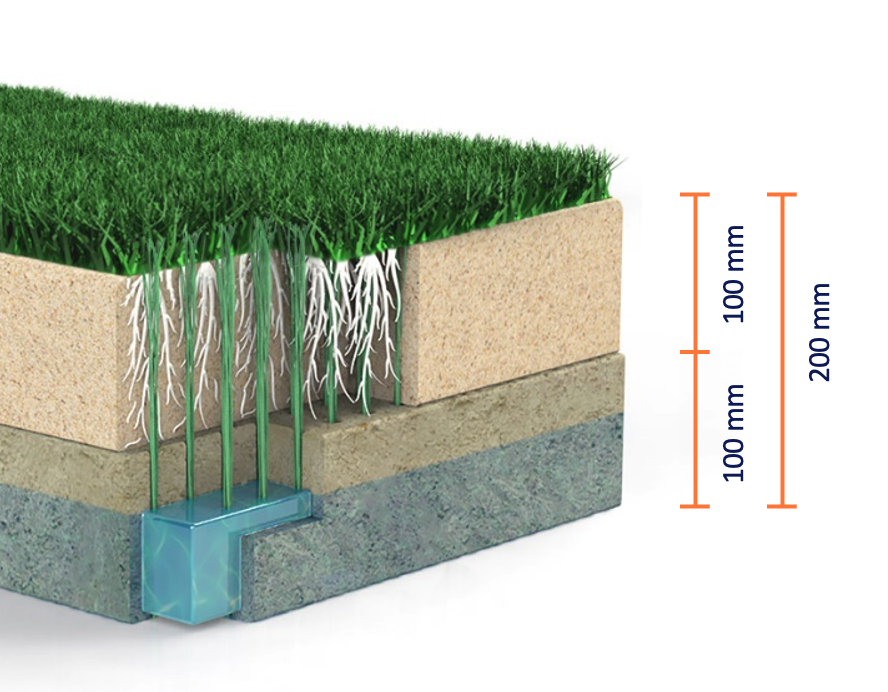

CONSTRUCTION OF HYDROFIELDS

Easy, fast, cost effective and a true reinforcement

Hydrofields as a system is based on Hydrorock – panels made of stone wool. Within the system Hydrorock in the first place is as a substantial part of the total construction due to its high density and at the same airlasticity, secondly it functions as a water management system making a traditional drainage system superfluous, and thirdly because it is a growing layer because it provides water and oxygen encouraging roots to grow deep and remain safely below ground, allowing the natural grass to become strong and fully established.

Total height 200 mm

- 100 mm Hydrorock

- 100 mm sand layer with final 5-8 evt with substrate mix

YOUR DECISION

Open (permeable) or closed (non-permeable) construction?

Depending on your location, local cicurmstances, the surroundings of the object, climate, the availability of water, etc., etc. one should decide first of all if the Hydrofields system will be build to collect water (closed system) , or to create an aquifer layer (open construction) to balance the natural habitat.

If, for example, in the area you want to construct the Hydrofields there is a lot of water due to a high ground water level, or due to heavy rainfall, it would be preferable to choose for an open construction. However, if one wants to re-use the water from rainfall or irrigation, the closed construction allows you to collect and reuse excess water for a variety of purposes.

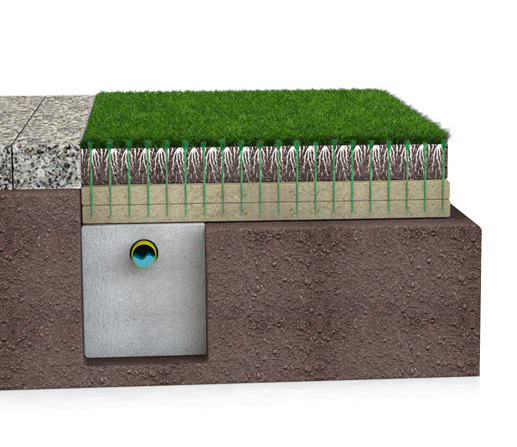

OPEN OR CLOSED CONSTRUCTION

OPEN CONSTRUCTION

The Hydrorock elements allow to make space for water to prevent onsite flooding and drought. Water is retained within the capillaries of the Hydrorock elements or moved in and out through them by water pressure differential between inside the block and the surrounding soil. When the water pressure is equal between the Hydrorock and the soil, water is retained within the block. As the moisture level of the soil drops as it dries, so does the water pressure and water is released from Hydrorock into the soil.

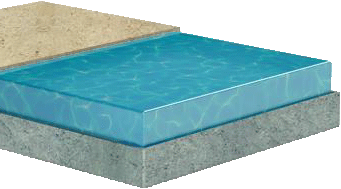

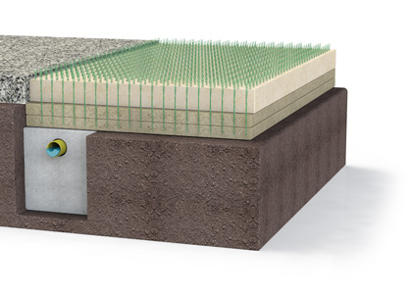

CLOSED CONSTRUCTION

The implementation of an impermeable layer makes it possible to collect and reuse excess water in an efficient way, for example for washing machines, showers, irrigation, etc.

CONSTRUCTION STEPS

![]() 2 – 3 days

2 – 3 days

1 – Excavation, levelling and compaction

- 200 mm excavation of the existing soil

- Excavate trench of (H) 360 mm x (W) 330 mm for the Hydrorock BD element

- Levelling and compaction of the subgrade

![]() 1 day

1 day

2 – Installation BD elements with drainpipe

- Installation of Hydrorock BD element (L 1200 x H 360 x W 330 mm)

- Hydrorock BD elements function as perimeter drainage

![]() 1 – 2 days

1 – 2 days

3 – Installation of the Hydrorock Panel

- Installation of 2 layers of HydrorockTM panel with (L) 1000mm x (W) 1000 mm x (H) 50 mm, total height 100 mm

![]() 2 – 3 days

2 – 3 days

4 – Installation of sand layer

- Installation of sand layer with a height of 100 mm

![]() 7 – 9 days

7 – 9 days

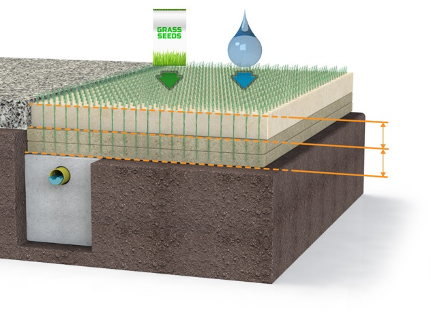

5 – Stitching of the artificial grass fibers

- Stitching of the artificial grass fibers by means of the GrassMax equipment

- Stitching depth ca. 130 mm

- Free pile height 20 mm

![]() 1 day

1 day

6 – Seeding and watering of the natural grass

- Seeding of natural grass

- The type of grass will be determined depending on the location and local circumstances of the field

- After seeding watering the total area

- Water will be stored in the Hydrorock layer

ANIMATION CONSTRUCTION