Products A – Z

Our complete portfolio of products for sports and sport infrastructure.

Solar

TUOsolar solar lighting with a unique design and state-of-the-art technology.

Hydrorock

Hydrorock offers solutions for separating rainwater, water buffering, drainage, infiltration and irrigation by using stone wool as basis material.

Reinforced grass

100%-natural grass cover reinforced with synthetic fibers to increase the hours a play.

HYDROFIELDS AT

It is different and you will feel it…

We are getting closer and closer, but let’s be honest: artificial turf is not like natural grass. It is a different kind of surface that has its own playing characteristics which requires a different kind of agility and physical strain of the players

Hydrofields AT, artificial turf with Hydrorock, has some advantages that brings the characteristics of the system closer to natural grass.

- Due to the fibrous structure of the Hydrorock base layer, it provides high energy restitution. This has a positive effect on fatigue and also lowers the physical load of the players. The effect of “feeling tired” and the risk of injury are minimized compared to conventional artificial turf systems.

- The infill layer consists of ca. 42kg/m² of sand as stabilizing infill and ca. 6kg/m² of performance infill. This composition results in high stability which, in combination with the energy restitution of Hydrorock, gives the players an overall similar experience to natural grass.

- Furthermore, the total structure of the system provides a stable and homogenous playing surface whereas performance is uniform and consistent all over the playing area.

- As Hydrorock is resistant to humidity and climate impact and retains its characteristics overtime, performance and playing quality are consistent.

WHY HYDROROCK

Good for the players

Hydrorock combines air with elasticity, just like jogging shoes.

YOUR BENEFIT?

- Force reduction=Energy return

- You will feel less tired

- Risk of injury is minimized

- Consistent impact protection

There is ca. 42 kg/m2 of sand and on top of the sand a layer of granules of only 10 mm (= 6 kg/m2).

YOUR BENEFIT?

- High stability because of a substantial layer of sand

- Extremely good traction for better control while running and playing

The total structure of the system – from bottom to the top – allows for a stable and homogenous playing surface.

YOUR BENEFIT?

- Layer of sand will provide a constant layer that will not change

- Hydrorock will provide the combination of air with elasticity

- Due to the energy return the total construction will not compact

- Playing characteristics are at a high level and consistent in time.

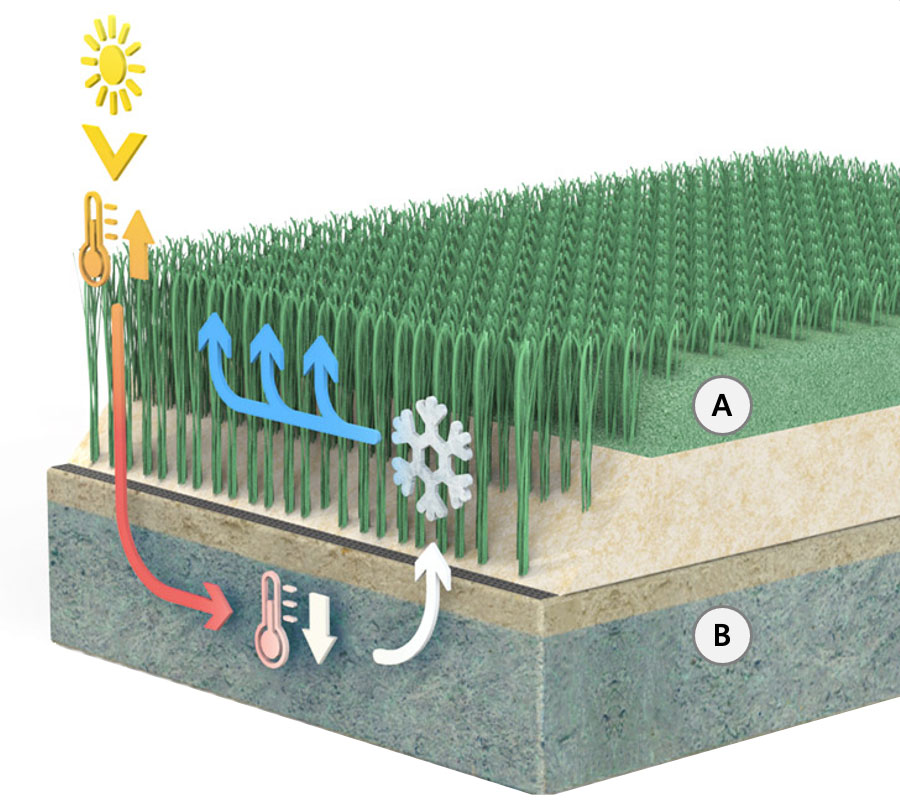

Whereas natural grass has a cooling effect, artificial turf does not. Artificial grass heats up in the sun and you will need water to cool it down. Hydrofields AT has 2 key elements to provide a cooling down effect that reduces the temperature up to 20 °C, which are:

A. Progran ECO, an infill mixture with zeolite

B. Hydrorock

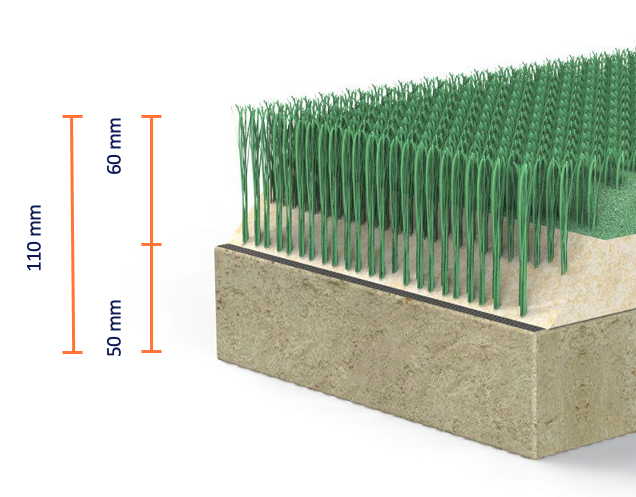

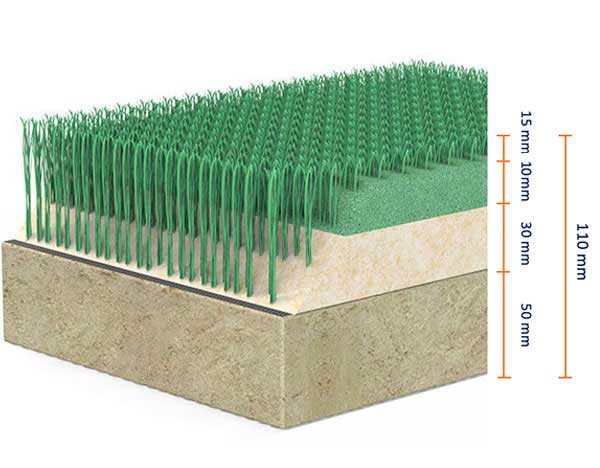

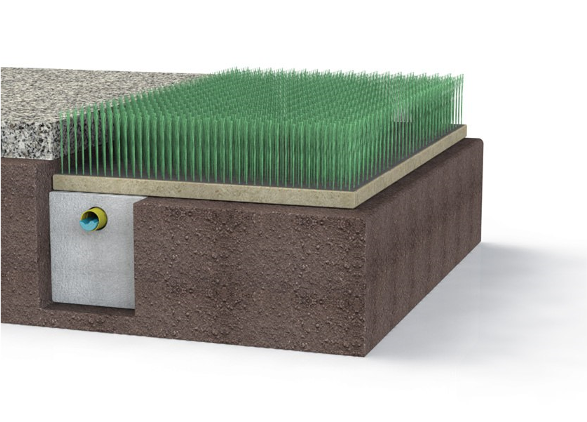

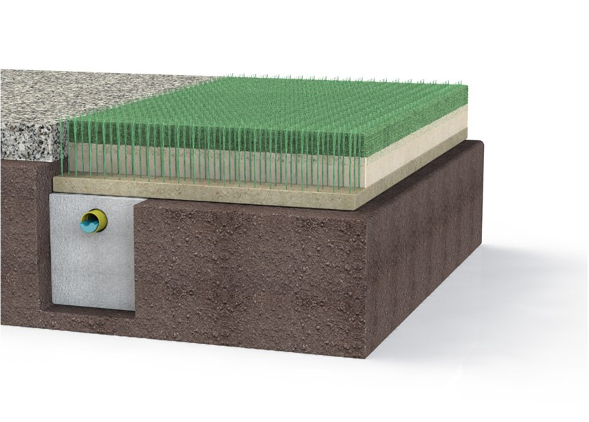

CONSTRUCTION OF HYDROFIELDS AT

Easy, fast and cost effective

Hydrofields AT is a system is based on Hydrorock – panels made of stone wool. Within the system Hydrorock in the first place is a substantial part of the total construction due to its high density, secondly it functions as a water management system making a traditional drainage system superfluous, and thirdly because Hydrorock gives energy back to the players due to its airlasticity and therefore has a positive effect on fatigue and the physical load of the players.

Total height 110 mm

- 50 mm Hydrorock

- 60 mm artificial turf

with:

- 30 mm stabilizing infill (sand, ca. 42 kg/m2)

- 10 mm performance infill (Progran Eco, ca. 6 kg/m2)

- 15 mm free pile height

YOUR DECISION

Open (permeable) or closed (non-permeable) construction?

Depending on your location, local cicurmstances, the surroundings of the object, climate, the availability of water, etc., etc. one should decide first of all if the Hydrofields system will be build to collect water (closed system) , or to create an aquifer layer (open construction) to balance the natural habitat.

If, for example, in the area you want to construct the Hydrofields there is a lot of water due to a high ground water level, or due to heavy rainfall, it would be preferable to choose for an open construction. However, if one wants to re-use the water from rainfall or irrigation, the closed construction allows you to collect and reuse excess water for a variety of purposes.

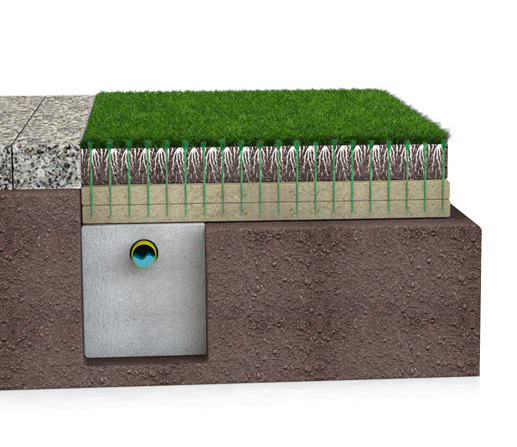

OPEN CONSTRUCTION

The Hydrorock elements allow to make space for water to prevent onsite flooding and drought. Water is retained within the capillaries of the Hydrorock elements or moved in and out through them by water pressure differential between inside the block and the surrounding soil. When the water pressure is equal between the Hydrorock and the soil, water is retained within the block. As the moisture level of the soil drops as it dries, so does the water pressure and water is released from Hydrorock into the soil.

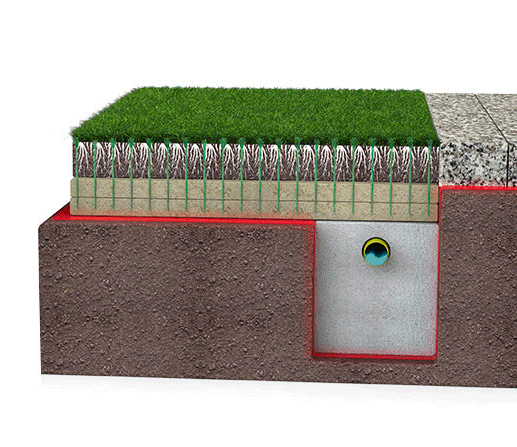

CLOSED CONSTRUCTION

The implementation of an impermeable layer makes it possible to collect and reuse excess water in an efficient way, for example for washing machines, showers, irrigation, etc.

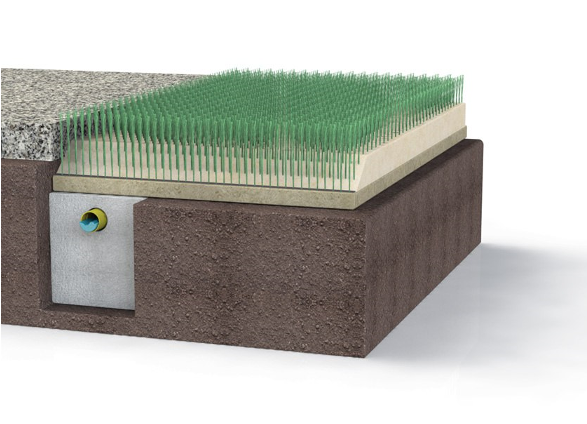

CONSTRUCTION STEPS

![]() 2 – 3 days

2 – 3 days

1 – Excavation, levelling and compaction

- 90 mm excavation of the existing soil

- Excavate trench of (H) 360 mm x (W) 330 mm for the Hydrorock BD element

- Levelling and compaction of the subgrade

![]() 1 day

1 day

2 – Installation BD elements with drainpipe

- Installation of Hydrorock BD element (L 1200 x H 360 x W 330 mm)

- Hydrorock BD elements function as perimeter drainage

![]() 1 – 2 days

1 – 2 days

3 – Installation of the Hydrorock Panel

- Installation of the Hydrorock panel with (L) 1000mm x (W) 1000 mm x (H) 50 mm

![]() 3 – 5 days

3 – 5 days

5 – Installation artificial grass

- Installation of the artificial turf with pile height 60 mm

![]() 1 – 2 days

1 – 2 days

6 – Installation of stabilizing infill

- Installation of ca. 42 kg/m2 of sand as stabilizing infill material which results in an infill height of ca. 35 mm

![]() 1 – 2 days

1 – 2 days

7 – Installation of performance infill

- Installation of ca. 5,5 kg/m2 of granules as performance infill material which results in an infill height of ca. 10 mm

ANIMATION CONSTRUCTION